Keywords:

Keywords:

Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Keywords:

It has been estimated that, by 2050, the world will need to produce 70% more food than in 2005, and will need 50% more fresh water and fuel, while reducing CO2 emissions by 100%. These are massive global challenges that are not going to be solved by current technologies, which is why international teams at the Centre for Solar Biotechnology, based at the Institute for Molecular Bioscience (IMB) at The University of Queensland, Australia, are working with a wide range of industry partners to advance novel algae-based solutions to tackle these issues.

The global population is estimated to grow from around 7.8 billion to 9.8 billion people in the next 30 years, and we will need extra food, fuel and water to survive. With our water and agricultural resources already stretched, where is all the extra going to come from? Professor Ben Hankamer, Director of the IMB Centre for Solar Biotechnology, explained why many researchers are now turning to algae as a renewable source for various products: “Algae are a diverse group of aquatic organisms that are increasingly being used to provide sustainable solutions to global problems. Many species of algae can be grown in saltwater, on non-arable land, and they also absorb sunlight and CO2. This opens up a huge opportunity to expand large scale solar biotechnologies onto areas of land that would otherwise be non-productive, as well as into the oceans, using the Sun’s energy to fuel the world’s future needs.”

Laboratory automation is essential for the Centre for Solar Biotechnology’s high throughput screening approaches (NOTE: Photo taken prior to social distancing)

Laboratory automation is essential for the Centre for Solar Biotechnology’s high throughput screening approaches (NOTE: Photo taken prior to social distancing)

The Centre for Solar Biotechnology has 30 research teams across Australia, New Zealand, Europe, Asia and the USA working on different aspects of algae, including collection and characterization of new species, development of novel strains and products using synthetic biology and gene editing technology, optimization of production and downstream processes, and techno-economic feasibility studies that are essential for successful scale-up and commercialization of algal products. Ben continued: “We are working towards the development of advanced algae technologies for the production of fuels, food, livestock feeds and therapeutic proteins, and have connected with numerous industries and research institutes to further those projects. This ensures that we are well informed of what’s required, and how we can advance the fundamental science behind these products to deliver what the industry needs.”

Juliane Wolf, researcher and manager of the Centre for Solar Biotechnology pilot plant, is guiding systems automation for high throughput analysis and system scale-up. She explained: “We have two Tecan systems that are used on various projects, helping us to develop high throughput screening approaches to select certain characteristics, as well as to optimize the production of specific microalgae. We’ve developed these instruments to meet our exact needs with assistance from Tecan’s capable team. One has been adapted for the growth of photosynthetic microalgae by adding three shaker modules, each holding six multi-well plates, and sealing the chamber to control atmospheric conditions.1 We then integrated LEDs for every well of a 96-well plate to enable independently-controlled light conditions, allowing us to simulate weather patterns or conditions inside an algae culture.2 This platform also has a Robotic Manipulator Arm™ that transfers the plates from the shakers to the onboard spectrophotometer for optical density and fluorescence measurements. It allows us to check the responses of the microalgae to different illumination settings to determine the best conditions for growth.3 One of the great things about this automated set-up is that it allows us to measure the density for each of the 1,728 algae cultures every three hours, day and night, for three days – the throughput is excellent and we can gather an amazing amount of data this way.”

One of the great things about this automated set-up is that it allows us to measure the density for each of the 1,728 algae cultures every three hours, day and night, for three days.

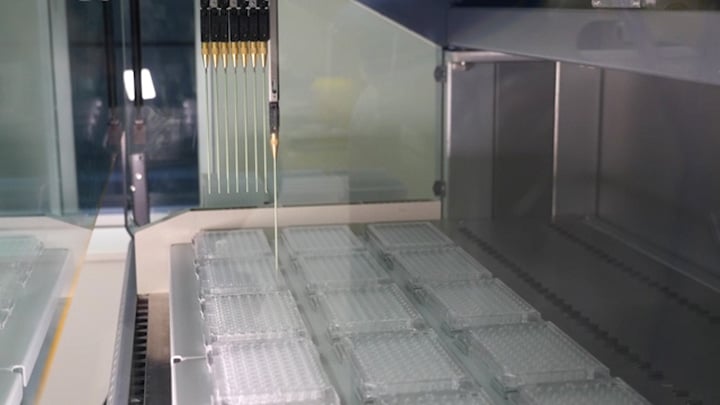

As well as optimizing the light conditions, different nutrients also need to be tested in order to provide the best synthetic efficiency. Ben continued: “The second instrument has a Liquid Handling Arm™ that we use to explore media compositions and screen different growth conditions to optimize the nutrients for every strain individually. There can be up to 20 different nutrients for each species and, if you decided to test every combination at only three concentrations, you would quickly end up with a large number of individual conditions that you need to investigate, making the design of statistically compressed and automated screens essential.” Juliane picked up the story: “I developed a statistical approach to identify high performance production conditions for 100 microalgae cell lines, which meant conducting more than 25,000 individual experiments.4 The power of the Tecan instruments is that they allow us to investigate and analyze these complicated data sets and find something close to the optimum. This would be impossible using manual screens.”

The team uses a Freedom EVO® to optimize media compositions for up to 20 different nutrients

The team uses a Freedom EVO® to optimize media compositions for up to 20 different nutrients

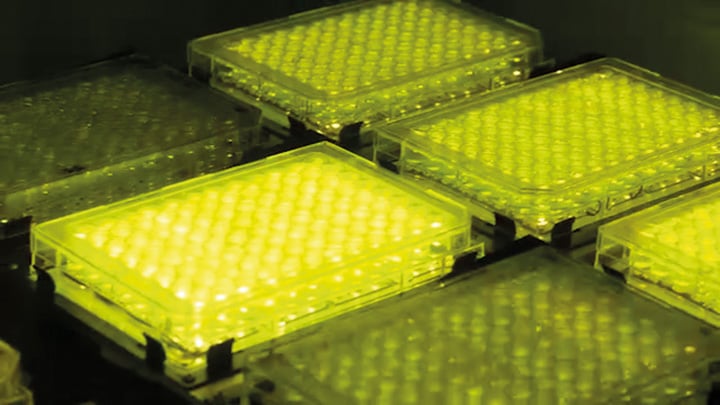

Integrated LEDs are used to simulate various weather patterns

Integrated LEDs are used to simulate various weather patterns

“We looked at a number of different systems for this application and thought that the Tecan instruments were the best fit and gave us the most capabilities. We’ve been using the platforms for a while now and are very happy with the work that they have enabled; they have really contributed to the robustness of our experiments and have increased our throughput immensely. The local Tecan engineers have been fantastic in helping us to adapt the systems for our workflow, and we are now involved in building a large, collaborative research project within the industry to assist with system scale-up. These kinds of projects are driven forward by everyone working together, and we look forward to seeing what we can achieve,” Ben concluded.

To find out more about Tecan’s synthetic biology solutions, visit www.tecan.com/synthetic-biology

To learn more about the Centre for Solar Biotechnology, go to www.imb.uq.edu.au/solar

Keywords: